BSL-3 mobile-laboratories

BSL-3 Mobile Laboratory

Spectevo Technologies Mobile Biocontainment Laboratories offer the ideal solution for providing surge capacity for laboratory services during periods of emergency. By utilizing a fully equipped turnkey, Mobile Biocontainment Laboratory, facilities are able to rapidly increase their volume without sacrificing capabilities. Each mobile facility is engineered and constructed to meet or exceed the CDC NIH BMBL 5th Edition guidelines and the World Health Organization (WHO) guidelines for BSL-3 laboratories.

Applications:

Emergency Disease Surveillance

Temporary Laboratory Space during facility down time

Laboratory Swing Space

Any application where microbiological containment laboratory space is required

Six decades of Spectevo Technologies manufacturing excellence has delivered a proven track record of deploying critical advanced laboratory capacity globally. Spectevo Technologies mobile containment laboratories are designed by a team of biocontainment experts to provide the optimal safety for the handling of biologically contaminated materials.

This allows the facility to be effectively utilized for manipulating samples required to be handled in a containment laboratory environment. Spectevo Technologies is the only manufacturer that provides a single-source, OEM solution for both the laboratory and all critical containment equipment. Spectevo Technologies cutting-edge engineering teams and subject-matter experts are located at a 173,000ft2 US manufacturing plant. Spectevo Technologies turnkey mobile units meet the most stringent biocontainment requirements and provide critical infrastructure for global health security.

Mechanical Specifications:

A heating, ventilation and air conditioning (HVAC) system is installed in the facility. The HVAC system is engineered to maintain a comfortable working temperature and humidity, and provides an inward flow of air into the laboratories. In the BSL-3 Laboratory, the mechanical ventilation also prevents recirculation to spaces outside of the laboratory.

Electrical Specifications:

Laboratories are designed to be powered from shore power and are equipped with an automatic transfer switch for integration to locally available generators to provide redundancy in case of power outages or fluctuations.

- Connections for utility power and/or auxiliary generator inputs are provided via transfer switch.

- Region-specific electrical configuration

- Standard Power Requirements:

- 110-230V, 50/60Hz, 3Ph, 160kVa

- Single point connection

- Shore power inputs are provided

- Onboard Diesel Generator provided for critical systems.

Plumbing Specifications:

The Trailer Laboratory Plumbing System provides fresh water to the three sinks and shower from the onboard 80 gallon (303 liter) Fresh Water tank. The two laboratory sinks have individual point-of-use sump pumps which transfer the sink waste water directly to the onboard 90 gallon (341 liter) Gray Water Waste tank. The Shower drain & Shower Room sink have one point-of-use sump pump. The sump pump outlet ports are connected to the Gray water waste tank. The waste tank’s drain port is connected to the sanitary sewer to drain continuously or is closed to temporarily hold the waste water until it can be connected to a sanitary sewer line.

Interior Materials:

Walls and Ceiling - Seamless wall system,

Panels come in 40 foot lengths to minimize wall seams corners permanently sealed with an epoxy compound specifically designed for this purpose.

The end result is a monolithic barrier that is durable and easily cleaned.

Flooring:

Finished floor will be a high performance, homogenous, welded seam sheet polyurethane floor.

Casework:

Type 304 Stainless Steel work casework

Purpose built, all welded construction with adjustable shelving

Design Excellence:

Spectevo Technologies Mobile Biocontainment Laboratories are designed to be exceptionally durable. To achieve this, only the highest grade, cleanroom-compatible materials are used in the facility’s construction.

The interior walls are constructed of a high performance composite that provides a seamless interior suitable for frequent wash-downs with sanitizing agents as well as gas bio-decontamination.

The floor is seamless vinyl, coved up the walls, and epoxy-sealed to the walls for ease of cleaning.

All work surfaces are seamless stainless steel with casework designed for gas and vapor phase decontamination. Surfaces are coved for easy spill cleanup and sanitization. Edges are rounded and polished to avoid snagging Personal Protective Equipment (PPE).

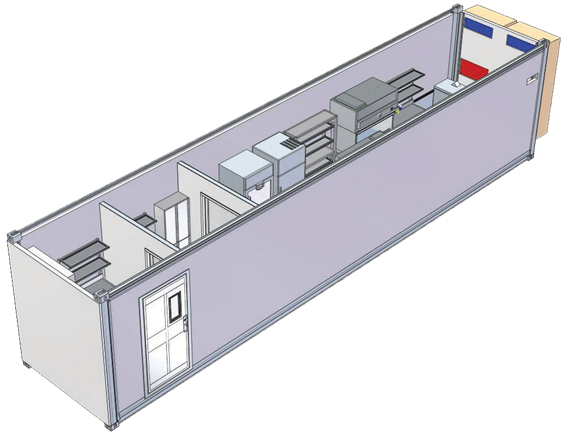

Trailer External Dimensions:

528” (13.4M) L x 101 3/4”(2.59M) W x 130” (3.3M) H

Laboratory Command Center

Internal Dimensions:52” (1.32M) L x 95 1/4”(2.42M) W x 96” (2.44M) H

BSL-2 Laboratory (PCR PREP)

Internal Dimensions:136” (3.45M) L x 95 1/4”(2.42M) W x 96” (2.44M) H

BSL-3 Anteroom/Shower Room Internal Dimensions:

67 5/8” (1.72M) L x 40” (1M) W x 96” (2.44M) H

BSL-3 Laboratory Internal Dimensions:137 7/8” (3.5M) L x 95 1/4”(2.42M) W x 96” (2.44M) H

Spectevo Technologies BSL-3 Mobile Biocontainment Laboratories are designed with

4 Distinct Spaces:

Laboratory Command Center:

The Laboratory Command Center serves as the main entrance to the Mobile Biocontainment Laboratory and the main entrance door is equipped with the proper security for your application.

BSL-2 Laboratory:

This BSL-2 Laboratory area exceeds BMBL 5th edition Laboratory Facility guidelines for BSL-2 as well as World Health Organization (WHO) guidelines for BSL-3 laboratories. The room air is both supplied and externally exhausted through HEPA filters.

The room is equipped with two (2) Class II, Type A Biological Safety Cabinets to protect the product and personnel.

Ample storage space is provided by the custom casework as well as an integrated refrigerator and freezer. All casework is stainless steel with seamless welds, coved corners and radiused edges and is compatible with all standard gas and vapor decontamination systems.

A top-loading autoclave is provided for sterilization.

BSL-3 Laboratory:

This BSL-3 Laboratory area exceeds the CDC NIH BMBL guidelines and the World Health Organization (WHO) guidelines for BSL-3 laboratories. The room is supplied with HEPA filtered air and the return air is HEPA filtered before being exhausted out of the laboratory.

The room is equipped with a Class III Biological Safety Cabinet (Glovebox) for receiving unknown or extremely hazardous samples.

A stainless steel pass-through airlock chamber integrated to the glovebox has three interlocked doors that allow samples to be introduced from the outside environment directly to the Class III glovebox. On the outside of the laboratory, a door will open to expose the sample entry airlock. The three-door airlock also permits safe movement of items between the glovebox and the BSL-3 laboratory. (One door opens to the exterior of the lab, one into the glovebox, and one into the BSL-3 laboratory.)

The electromechanical interlock system controlled by a programmable logic controller (PLC) prevents more than one airlock door being open at any time. If any door is open, the other two will remain locked until the open door is closed. This prevents breach of containment, eliminating the risk of contaminating work spaces or the environment.

The airlock is maintained under negative pressure. The inlet air that purges the chamber is HEPA filtered. The exhaust air is HEPA filtered through the filtration system of the glovebox.

Ample storage space is provided by the custom casework as well as an integrated refrigerator and freezer. All casework is stainless steel with seamless welds, coved corners and radiused edges and is compatible with all standard gas and vapor decontamination systems.

A top-loading autoclave is provided for sterilization.

Spectevo Technologies Mobile Biocontainment Laboratories are delivered fully-equipped and ready for on-site commissioning. The standard configuration consists of:

Laboratory Command Center

- Stainless steel countertops with seamless welds, coved corners and radiused edges

- Stainless steel casework

- Security, Data and Environmental Monitoring are all accessible from the office area (see related sections)

BSL-2 Laboratory

- Custom casework provides ample storage space

- Two (2) Class II Type A Biosafety Cabinets

- Outer cabinet and work surface are welded stainless steel with a #4 pharmaceutical grade finish

- Front lifting viewing panel is easily removed and is gasketed to provide a proper seal when in place

- Ergonomic front panel of the biological safety cabinet is concave permitting operator to lean into work area, enhancing user comfort

- High capacity motor/blower system with speed control to extend the life of the HEPA filter

- Supply and exhaust HEPA filters are parallel to work area and each other to prevent turbulence

- Removable stainless steel work tray and tray supports facilitate easy clean up of the biological safety cabinet

- Separate lighted power ON/OFF indicator switches for blower and lighting

- Electrical is 115 Volt, 60 Hz

- 220/50-60 Hz also available

- Ten foot power cord with molded grounded plug

- Constructed to allow for optional outside venting of exhaust air from the biosafety cabinet

- Material pass box with HEPA-purge pass-through connecting the BSL-2 Laboratory and the BSL-3 Laboratory

- Allows the transfer of materials from either of the laboratories into the BSL-3 Laboratory or vice-versa while maintaining containment

- Interlocked doors assure that the airlock is never open on both sides simultaneously

- HEPA-purge cycle removes particulates within the airlock, achieving ISO Class 5 conditions before the materials are removed

- Standard laboratory refrigerator

- Standard laboratory freezer

- The preparation areas consists of stainless steel countertops with seamless welds, coved corners and radiused edges

BSL-3 Laboratory

- Class III Biological Safety Cabinet (Glovebox)

- 4’ wide, with three gloveports

- One three-door airlock for receiving samples from outside of laboratory

- Custom casework provides ample storage space

- Standard laboratory refrigerator

- Standard laboratory freezer

- Top-loading autoclave

- The preparation areas consist of stainless steel countertops with seamless welds, coved corners and radiused edges

A stainless steel pass-through airlock chamber integrated to the glovebox has three interlocked doors that allow samples to be introduced from the outside environment directly to the Class III glovebox.

Controls, Communications & Recording Systems

Communication Ports

(12) Data ports are provided for network instruments, computer workstations and printers. Cables are run in shielded chases to a patch panel in the anteroom. Telephone port is provided in the Laboratory Command Center.

Also included:

- Intercom System

- Fire / Burglar System

- BMS – Environmental Monitoring

- Cameras and Monitors

- Digital video cameras and a digital video recorder (DVR) provide perimeter security. Interior and exterior cameras provide live local video.

- CCTV system (8 cameras, DVR capable of recording 30 days of video)

- Data / Phone Network

- All data terminated into a patch panel in the command center

- Computer and printer provided by end user

- Data rack can support customer supplied switch

- Cables in shielded chases

- Telephone port will be provided in the Laboratory Command Center

- Keyless entry main door

- Testing & Quality Control

- Quality Process is designed to evaluate performance as well as fit and finish of every system on our mobile platform. Evaluation and testing is conducted on all components and aspects of the facility.

Gallery

CREATING ENVIRONMENTS THAT SERVE LIFE SCIENCE INNOVATION AND ADVANCE GLOBAL HEALTH

Delivering the ultimate versatility to your laboratory solution, Spectevo’s Van Labs are fit for the challenge wherever needed.